Water Filtration Units for Open and Closed Cooling Systems eJCX

LAKOS eJCX Water Filtration Units for Open and Closed Cooling Systems eJCX keep cooling tower basins free of suspended solids that cause scale, corrosion, fouling and biological activity.

Description

Water Filtration Units for Open and Closed Cooling Systems

LAKOS eJCX

LAKOS eJCX Water Filtration Units for Open and Closed Cooling Systems eJCX keep cooling tower basins free of suspended solids that cause scale, corrosion, fouling and biological activity.

Controlling these factors leads to lower maintenance, improved chemical effectiveness, longer cooling tower and downstream equipment life, and a significant decrease in long-term water and energy costs.

- Premium Efficiency centrifugal filtration, independently tested, rated to remove up to 98% of solids 44 microns and larger in a single pass, and up to 99% of solids 25 microns and larger in recirculating applications.

- eJCX Systems feature LAKOS eJPX Centrifugal Separator, Premium Efficiency pump, higher capacity (12 liters) Solids Recovery Vessel and/or Fail-Safe Automated Purge valve.

- Minimize tower nozzle clogging, protect basin floor from under-deposit corrosion, eliminate risk of injury associated with manual basin cleaning, and greatly reduce heat transfer loss in downstream equipment.

Basin Sweeping Flow Range: 110 – 1.110 US GPM (25 – 252 m3 /hr)

Side Stream Flow Range: 140 – 1.110 US GPM (32 – 252 m3 /hr)

Filtration level: Removes fine solids 25 microns and larger

Why Does My Cooling Water Need Filtration? |

||

|

|

|

Cooling TowerSuspended solids clog tower nozzles and water distribution systems – resulting in a loss of thermal capacity as well as scale and mineral buildup on tower fill and closed tower coils. |

Condenser TubeSuspended solids reduce heat transfer areas and decrease flow inside tubes by accumulating on internal tube fins. |

Heat Exchanger PlateSolids in cooling tower water clog channels and create areas of low thermal conductivity. |

Eliminate Basin Cleaning |

|

|

Premium Efficiency Basin SweepingTraditional side stream filtration systems take a percentage of the flow (generally 10-25% or less) from the main line using a by-pass directly to the filtration system. The filtered water is then returned to the main line. Basin sweeping is simply relocating the traditional side stream filtration system from the main line directly to the cooling tower basin, thus increasing the percentage of side stream filtration to 20% or more.

Basin Sweeping Systems have an additional advantage by recirculating the filtered water through a network of pipes and nozzles that agitate and direct other settled and suspended debris in the basin towards the filtration system – and away from the condenser water pump. Basin Sweeping capacity is determined by the volume of water in the basin rather than assigning a percentage of the full flow, as is commonly done with traditional side stream applications. |

||

|

|

Economical Side-Stream Filtration |

Premium Efficiency Side Stream CleaningUsing a LAKOS System in Side Stream applications helps reduce suspended solids in mainstream flow, there by reducing downstream heat transfer loss.

Features and benefits:

|

||

Maintain Closed Loop Efficiencies |

|

|

Premium Efficiency Closed Loop FiltrationUsing a LAKOS System for closed loop filtration provides 24/7 filtration with zero system downtime, consistent pressure loss, and no backwash requirements.

Features and benefits:

|

||

Basin Sweeping Specifications

|

High Efficiency Models |

Downloads |

Flow Rates1 m3/hr |

Diffuser/ Strainer Inlet3 |

Separator Outlet |

Weight |

Pump HP/kW2 |

|

eJCX-0110-EFS eJCX-0110-SRV |

25 | 3″ | 2″ | 314 | 3 HP/2.23 kW | |

|

eJCX-0160-EFS eJCX-0160-SRV |

36 | 4″ | 2-1/2″ | 396 | 5 HP/3.72 kW | |

|

eJCX-0210-EFS eJCX-0210-SRV |

48 | 4″ | 3″ | 465 | 7.5 HP/5.59 kW | |

|

eJCX-0310-EFS eJCX-0310-SRV |

70 | 6″ | 4″ | 600 | 7.5 HP/5.59 kW | |

|

eJCX-0410-EFS eJCX-0410-SRV |

93 | 6″ | 4″ | 600 | 10 HP/7.45 kW | |

|

eJCX-0610-EFS eJCX-0610-SRV |

139 | 6″ | 4″ | 762 | 20 HP/14.8 kW | |

|

eJCX-0910-EFS eJCX-0910-SRV |

207 | 8″ | 6″ | 1231 | 25 HP/18.7 kW | |

|

eJCX-1110-EFS eJCX-1110-SRV |

252 | 8″ | 6″ | 1402 | 30 HP/22.4 kW |

Side Stream and Closed Loop Specifications

|

High Efficiency Models |

Downloads |

Flow Rates1 m3/hr |

Diffuser/ Strainer Inlet3 |

Separator Outlet |

Weight |

Pump HP/kW2 |

|

eJCX-0110-EFS eJCX-0110-SRV |

32 | 3″ | 2″ | 314 | 3 HP/2.23 kW | |

|

eJCX-0160-EFS eJCX-0160-SRV |

45 | 4″ | 2-1/2″ | 396 | 5 HP/3.72 kW | |

|

eJCX-0210-EFS eJCX-0210-SRV |

57 | 4″ | 3″ | 465 | 7.5 HP/5.59 kW | |

|

eJCX-0310-EFS eJCX-0310-SRV |

80 | 6″ | 4″ | 600 | 7.5 HP/5.59 kW | |

|

eJCX-0410-EFS eJCX-0410-SRV |

111 | 6″ | 4″ | 600 | 10 HP/7.45 kW | |

|

eJCX-0610-EFS eJCX-0610-SRV |

139 | 6″ | 4″ | 797 | 10 HP/14.8 kW | |

|

eJCX-0910-EFS eJCX-0910-SRV |

184 | 8″ | 6″ | 1061 | 15 HP/18.7 kW | |

|

eJCX-1110-EFS eJCX-1110-SRV |

252 | 8″ | 6″ | 1323 | 25 HP/22.4 kW |

Note: eJCX-0910, eJCX-1110, eJBX-0810, and eJBX-1110 units are 22 1/2° low profile.

1. Higher flow rates are available. Contact LAKOS.

2. Contact LAKOS for motor specific FLA.

3. Minimum suction pipe size is equivalent to the system’s diffuser inlet. Pump NPSHR and piping to-and-from LAKOS Systems should be reviewed and sized accordingly. Consult LAKOS for design assistance if the length of the suction line is more than 25′ or has several elbows or elevation changes.

Frequently Asked Questions

Answer: As a rule of thumb, LAKOS uses a sizing factor of 1 GPM per square foot of basin area to determine the required size of a Tower Clean (TC) system. Using this factor, multiply the square footage of the cooling tower basin (L x W) by 1 GPM / sq. ft. This gives the basic flow rate for sizing the TC system. Tower Clean literature LS-710 can also be used as a reference for more information and equipment selections.

For industrial applications or very heavy solids loadings, consult LAKOS for recommended basin sweeping flow rates.

Answer: LAKOS factory-built purge controllers (ABV, ABV2, AKE, APP, AFS, EFS) do not have factory-set timings. The required purge frequency and durations vary depending on flow rates, solids concentrations, type of solids, etc. The controller time settings must be set at installation and LAKOS literature LS-608 can be used to help establish purge duration and frequency based on the application.

Answer: To determine the necessary purge frequency, purge often at first and calculate the proper rate based on the expected volume of separated solids. Purge duration should be long enough to evacuate the purge chamber AND clear the entire length of the purge piping of all solids. This is usually indicated by a change in the color of the purged liquid from dark to light.

The time between purges should never exceed the time it takes to fill 1/3 of the collection chamber volume, based on the expected solids load and the separator’s purge collection volume, as indicated in the separator’s literature. Refer to LS-608 for additional information on calculating purge frequency and duration.

Answer: While there are many LAKOS Separators still in service after 15-25 years, there are many variables to the longevity of a LAKOS Separator. It can generally be expected to last as long as any other materials of similar construction in that system. Environment, fluid chemical make-up, flow, the material of construction, type of solids, and maintenance purging are all important factors to the life of a separator. It is important to consider all these factors when purchasing a separator. Providing LAKOS with details about your application will ensure your separator meets or exceeds the life expected through your purchase. Consult your LAKOS factory representative to obtain the life expectancy in your specific application.

Answer: Solids-removal efficiency is affected by several factors, including the difference in specific gravity between the solids and the carrying liquid, the viscosity of the liquid, the particle shape, and any purging enhancement techniques. In general, with a specific gravity ratio of 2.6 (e.g. quartz sand in freshwater), liquids of 31 SSU viscosity, and generally round particles, a single pass through a separator predictably removes 98% of particles 74 microns (0.0029 inches) and larger. Appreciable quantities of particles finer than 74 microns are also removed, as well as particles of lighter specific gravity. Higher specific gravities (like mill scale in water, where SG=5.7) result in much finer levels of filtration.

Recirculating systems (running the fluid through one or more separators continuously) can also result in appreciable removal of particles down as fine as 5 microns.

Contact us for assistance determining performance expectations on your specific application.

Answer: As a standard, most separators are available in mild carbon steel and 304L/316L-series stainless steels. Specially designed separators can also be constructed in most weldable metals, including, but not limited to: super duplex stainless steels, chrome-moly, titanium, Hastelloy, nickel alloys, and cupronickel. In special cases, separators can also be fabricated in plastic or fiberglass. For materials other than carbon and stainless steel, consult with LAKOS on the availability of your specific material requirements.

Answer: The LAKOS Separator is capable of working with any liquid that has a viscosity less than 20 mPas. The solids to be separated must also have a specific gravity at least 1.5 greater than the fluid. The greater the specific gravity of the separable solids and the lower the viscosity of the liquid, the better the LAKOS Separator will work. A good rule of thumb: if the solids settle within 3-4 minutes in your liquid, they will likely be separable with a LAKOS Separator.

Video

Removing Dirt and Sand From Cooling Towers, Heat Exchangers, and Chillers – LAKOS |

|

|

How To Keep Cooling Tower Basins Clean All The Time – LAKOS |

|

|

Benefits of Using LAKOS Cooling Tower Basin Cleaning |

|

|

Cooling Tower Basin Cleaning – LAKOS |

|

|

LAKOS – Three Minute Settling Test |

|

|

Dimensions

Dimensions

|

Models |

Dim A (mm) |

Dim B (mm) |

Dim C (mm) |

| eJCX-0110 | 762 | 1041 | 1321 |

| eJCX-0160 | 813 | 1016 | 1664 |

| eJCX-0210 | 914 | 1143 | 1853 |

| eJCX-0310 | 914 | 1219 | 2084 |

| eJCX-0410 | 914 | 1270 | 2237 |

| eJCX-0610 | 1016 | 1321 | 2610 |

| eJCX-0910 | 1067 | 1995 | 1739 |

| eJCX-1110 | 1053 | 2260 | 1926 |

| eJBX-0610 | 1067 | 1270 | 2610 |

| eJBX-0810 | 972 | 1995 | 1739 |

| eJBX-1110 | 1041 | 2260 | 1926 |

Note: Dimensions are for spatial considerations only. Do not pre-plumb based on the above dimensions. Contact factory for detailed dimensions.

Accessories

Electric Fail-Safe Valve (EFS)

| LAKOS Electric Fail-Safe Valve (EFS) is an excellent alternative to our standard Purge Valves as the EFS valve features a fail-safe option for when power is lost. If power is cut off during a purge cycle, the EFS valve uses its internal battery pack to close the valve – preventing an unexpected water loss scenario. The EFS Valve is available on all Industrial and HVAC series Separators and can be purchased with a new Separator or as a replacement for an existing valve. |

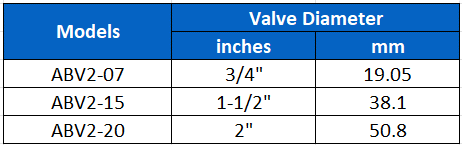

ABV2-Automatic Ball Valve

| The ABV2 purges solids automatically, eliminating manual purging. It also features an electronic circuit that adjusts motor speed to keep cycle time constant, maintaining consistent purge durations. Typical use cases are in HVAC or commercial applications. For residential applications, refer to our Accupurge valve. The ABV2 is also known as VB030 actuator.

|

HydroBoosters

SRV – Solids Recovery Vessel

|

| The Solids Recovery Vessel (SRV) captures purged solids and liquids and returns the clean liquid back to the system; resulting in a zero liquid loss solution. The SRV features continuous operation and allows for the removal of purged solids without interrupting system flow or filtration. SRV models come in three options: SRV-816, SRV-833, and SRV2-833.

|

Options

Inlet/Outlet Valve Kit Adders:

eTCV Valve Kit, 2 Tower Alternating Valve Kit

SRV Systems Adders:

SRI, DEC, Replacement Bags

Pump Repair Kit Adder

ASME

Internal 3M Scotchkote Coating:

Scotchkote internal coating is NSF/ANSI/CAN 61 certified. To view 3M’s NSF certification Click Here

Stainless Steel Material

Ask A Quote

Fill the form to get a quote or more information about the product.