Packaged Filtration Systems for Cooling Towers Basin TCX-TCI

LAKOS TCX-TCI Packaged Filtration Systems for Cooling Towers remove fine solids (44 microns and larger) from HVAC open and closed loops. This packaged system reduces manual basin cleaning, equipment operating costs, maintenance costs, and water use.

Description

Packaged Filtration Systems for Cooling Towers Basin

LAKOS TCX-TCI TowerClean

LAKOS TCX-TCI Packaged Filtration Systems for Cooling Towers remove fine solids (44 microns and larger) from HVAC open and closed loops. This packaged system reduces manual basin cleaning, equipment operating costs, maintenance costs, and water use.

- Filter performance rated to remove up to 98% of solids, 74 microns and larger, and up to 99% of solids 44 microns and larger in recirculating applications.

- TCX-TCI Systems include a Lakos Standard Efficiency Separator, High-Efficiency pump, standard capacity (6 liters) Solids Recovery Vessel and/or Automated Purge Valve.

- TCX-TCI systems are designed with a high head pump to effectively sweep and remove troublesome solids from Cooling Tower Basins.

Flow Range: 7 – 379 m³/hr

Maximum Pressure: 150 psi (10,3 bar)

Why Does My Cooling Water Need Filtration?

|

||

|

|

|

Cooling TowerSuspended solids clog tower nozzles and water distribution systems – resulting in loss of thermal capacity as well as scale buildup. |

Condenser TubeSuspended solids reduce heat transfer areas and decrease flow inside tubes by accumulating on internal tube fins.

|

Heat Exchanger PlateSolids in cooling tower water clog channels and create areas of low thermal conductivity.

|

Eliminate Basin Cleaning

Without filtration, dirt buildup quickly degrades the performance of your cooling tower, leading to increased energy costs and costly cleanouts. Automatic filtration keeps your tower efficient and eliminates cumbersome maintenance. Click Here to learn more about Cooling Tower Water Filtration.

|

|

Technical Specifications

|

TCI or TCX Models |

Downloads (TCI) |

Downloads (TCX) |

Flow m3/hr |

Inlet (grooved) |

Outlet (grooved) |

Inlet Piping To Use* |

Weight TCI (Kg) |

Weight TCX (Kg) |

Pump HP |

Max Basin Size (Sq. Ft.) |

Full Load Amp. @ 460v |

|

0030-SRV 0030-ABV |

7 | 1-1/2″ thd | 1″ | 2″ | 122 99 |

145 145 |

1 | 30 | 2.1 | ||

|

0065-SRV 0065-ABV |

15 | 2″ thd | 1-1/2″ | 2-1/2″ |

177 146 |

192 192 |

3 | 65 | 4.8 | ||

|

0100-SRV 0100-ABV |

23 | 3″ | 2″ | 3″ |

205 176 |

262 262 |

5 | 100 | 7.6 | ||

|

0145-SRV 0145-ABV |

33 | 3″ | 2-1/2″ | 4″ |

215 185 |

286 286 |

5 | 145 | 7.6 | ||

|

0200-SRV 0200-ABV |

45 | 3″ | 3″ | 4″ |

232 199 |

300 300 |

7.5 | 200 | 11 | ||

|

0280-SRV 0280-ABV |

64 | 4″ | 4″ | 6″ |

291 258 |

372 372 |

10 | 280 | 14 | ||

|

0400-SRV 0400-ABV |

91 | 6″ | 4″ | 6″ |

483 482 |

523 523 |

15 | 400 | 21 | ||

|

0525-SRV 0525-ABV |

119 | 6″ | 4″ | 6″ |

560 544 |

598 598 |

20 | 525 | 27 | ||

|

0600-SRV 0600-ABV |

136 | 6″ | 6″ | 6″ |

696 543 |

717 717 |

20 | 600 | 27 | ||

|

0825-SRV-L 0825-SRV-V 0825-ABV-L 0825-ABV-V |

|

|

187 | 8″ | 6″ | 8″ |

– 954 1010 924 |

– 803 980 803 |

30 | 825 | 40 |

|

1100-SRV-L 1100-SRV-V 1100-ABV-L 1100-ABV-V |

250 | 8″ | 6″ | 10″ |

1134 981 1038 970 |

974 838 1036 838 |

40 | 1100 | 52 | ||

|

1670-SRV-L 1670-ABV-L |

379 | 10″ | 8″ | 12″ |

1383 1394 |

1632 1632 |

50 | 1670 | 77 |

* LAKOS recommended inlet pipe size.

“L” stands for Low-Profile Orientation. “V” stands for Vertical Orientation

All TCX-TCI TowerClean systems are rated for 150 psi (10.3 bar) maximum pressure

Frequently Asked Questions

[/vc_column_text][/vc_column][/vc_row]

Answer: As a rule of thumb, LAKOS uses a sizing factor of 1 GPM per square foot of basin area to determine the required size of a Tower Clean (TC) system. Using this factor, multiply the square footage of the cooling tower basin (L x W) by 1 GPM / sq. ft. This gives the basic flow rate for sizing the TC system. Tower Clean literature LS-710 can also be used as a reference for more information and equipment selections.

For industrial applications or very heavy solids loadings, consult LAKOS for recommended basin sweeping flow rates.

Answer: LAKOS factory-built purge controllers (ABV, ABV2, AKE, APP, AFS, EFS) do not have factory-set timings. The required purge frequency and durations vary depending on flow rates, solids concentrations, type of solids, etc. The controller time settings must be set at installation and LAKOS literature LS-608 can be used to help establish purge duration and frequency based on the application.

Answer: To determine the necessary purge frequency, purge often at first and calculate the proper rate based on the expected volume of separated solids. Purge duration should be long enough to evacuate the purge chamber AND clear the entire length of the purge piping of all solids. This is usually indicated by a change in the color of the purged liquid from dark to light. The time between purges should never exceed the time it takes to fill 1/3 of the collection chamber volume, based on the expected solids load and the separator’s purge collection volume, as indicated in the separator’s literature. Refer to LS-608 for additional information on calculating purge frequency and duration.

Answer: LAKOS Centrifugal Separator Systems, such as TCX/TCI, remove dirt and debris by purging solids from the purge collection chamber (bottom of the Separator). This purge can be either controlled (open/close) via a Automated Ball Valve (ABV) or dumped into a Solids Recovery Vessel (SRV) for water recovery.

ABV (Automated Ball Valve) opens at pre-programmed intervals to dump purge contents (Dirt and Water) to drain or a collection tank. Learn more here.

SRV (Solids Recovery Vessel) features a bag filter connected to the LAKOS Separator purge that continuously dumps purge contents into a bag filter. This bag filter when filled with dirt can be periodically dumped. Water is recovered by piping the SRV to pump suction. Learn more here.

Answer: While there are many LAKOS Separators still in service after 15-25 years, there are many variables to the longevity of a LAKOS Separator. It can generally be expected to last as long as any other materials of similar construction in that system. Environment, fluid chemical make-up, flow, the material of construction, type of solids, and maintenance purging are all important factors to the life of a separator. It is important to consider all these factors when purchasing a separator. Providing LAKOS with details about your application will ensure your separator meets or exceeds the life expected through your purchase. Consult your LAKOS factory representative to obtain the life expectancy in your specific application.

Answer: Solids-removal efficiency is affected by several factors, including the difference in specific gravity between the solids and the carrying liquid, the viscosity of the liquid, the particle shape, and any purging enhancement techniques. In general, with a specific gravity ratio of 2.6 (e.g. quartz sand in freshwater), liquids of 31 SSU viscosity, and generally round particles, a single pass through a separator predictably removes up to 98% of particles 74 microns (0.0029 inches) and larger. Up to 98% of particles 44 micron and larger for eSeries (eHTX and eJPX) Separators. Appreciable quantities of particles finer than 44 microns (for eSeries Separators) are also removed, as well as particles of lighter specific gravity. Higher specific gravities (like mill scale in water, where SG=5.7) result in much finer levels of filtration.

Recirculating systems (running the fluid through one or more separators continuously) can also result in appreciable removal of particles down as fine as 5 microns.

Contact LAKOS for assistance determining performance expectations on your specific application.

Answer: As a standard, most separators are available in mild carbon steel and 304L/316L-series stainless steels. Specially designed separators can also be constructed in most weldable metals, including, but not limited to: super duplex stainless steels, chrome-moly, titanium, Hastelloy, nickel alloys, and cupronickel. In special cases, separators can also be fabricated in plastic or fiberglass. For materials other than carbon and stainless steel, consult with LAKOS on the availability of your specific material requirements.

Answer: LAKOS Separators and sand media filters are both designed to remove solids from liquids, but have advantages over each other depending on the application.

A separator is designed to remove solids with a specific gravity at least 1.5 times that of the carrying liquid. Separators require very little, if any, maintenance because they have no moving parts. The pressure loss across a separator is predictable and steady and only varies with flow rate. Separators require minimum liquid loss for the purging of collected solids, and can also be equipped with an optional Solids Recovery Vessel that can eliminate liquid loss. However, Separators do not generally help with liquid clarity (turbidity) and are ineffective on organic material, such as algae.

A sand media filter is designed to remove finer solids (down to 5 microns in size) with low specific gravities. Sand filters are used when finer filtration and liquid clarity (turbidity reduction) are a requirement. Sand filters do require more operational maintenance (more moving parts) and use more liquid for backwashing of the sand bed to remove the collected solids. Pressure loss across a media filter varies, as solids are collected and enter a backwash cycle when they reach a predetermined pressure loss. However, sand media filters are very efficient at removing a wide variety of light, organic solids.

Answer: The maximum solids loading on LAKOS Separators is recommended to be less than 1% by volume. While 1% may seem low, keep in mind that 1% in a small 100 GPM system is 1 gallon of solids every minute, or 1,440 gallons (twenty-six 55-gallon drums) of solids per day. If your application exceeds these limitations, please consult your factory representative for proven alternatives.

Answer: The LAKOS Separator is capable of working with any liquid that has a viscosity less than 100 SSU. The solids to be separated must also have a specific gravity at least 1.5 greater than the fluid. The greater the specific gravity of the separable solids and the lower the viscosity of the liquid, the better the LAKOS Separator will work. A good rule of thumb: if the solids settle within 3-4 minutes in your liquid, they will likely be separable with a LAKOS Separator.

Answer: Standard maximum temperature rating for operating most LAKOS Separators is 180°F. LAKOS can easily accommodate higher temperatures with custom separators.

Answer: Standard maximum pressure rating for most LAKOS Separators is 150 psi. Contact the factory for higher pressures; LAKOS can accommodate pressures up to 3000 psi through custom separators.

Video

Removing Dirt and Sand From Cooling Towers, Heat Exchangers, and Chillers – LAKOS |

|

|

How To Keep Cooling Tower Basins Clean All The Time – LAKOS |

|

|

Benefits of Using LAKOS Cooling Tower Basin Cleaning |

|

|

Cooling Tower Basin Cleaning – LAKOS |

|

|

LAKOS – Three Minute Settling Test |

|

|

DIMENSIONS TCI

|

TCI Models |

Dim A |

Dim B |

Dim E – TCI (mm) |

|

0030-SRV 0030-ABV |

1010 1010 |

610 610 |

1125 1124 |

|

0065-SRV 0065-ABV |

1010 1010 |

610 610 |

1119 1119 |

|

0100-SRV 0100-ABV |

1010 1010 |

610 610 |

1119 1119 |

|

0145-SRV 0145-ABV |

1010 1010 |

610 610 |

1207 1205 |

|

0200-SRV 0200-ABV |

1010 1010 |

610 610 |

1283 1283 |

|

0280-SRV 0280-ABV |

1010 1010 |

610 610 |

1575 1575 |

|

0400-SRV 0400-ABV |

1219 1219 |

762 813 |

1757 1757 |

|

0525-SRV 0525-ABV |

1219 1219 |

762 813 |

1757 1757 |

|

0600-SRV 0600-ABV |

1524 1524 |

914 914 |

2157 2157 |

|

0825-SRV-L 0825-SRV-V 0825-ABV-L 0825-ABV-V |

– 1524 2565 1524 |

– 940 1092 1016 |

– 2157 1439 2157 |

|

1100-SRV-L 1100-SRV-V 1100-ABV-L 1100-ABV-V |

2180 1524 2495 1524 |

915 1016 1016 1016 |

1439 2157 1435 2157 |

|

1670-SRV-L 1670-ABV-L |

2981 3258 |

1181 1283 |

1553 1553 |

DIMENSIONS TCX

|

TCX Models |

Dim A |

Dim B |

Dim E – TCX (mm) |

|

0030-SRV 0030-ABV |

1010 1010 |

610 610 |

1172 1172 |

| 0065-SRV

0065-ABV |

1010 1010 |

610 610 |

1172 1172 |

| 0100-SRV

0100-ABV |

1010 1010 |

610 610 |

1222 1222 |

| 0145-SRV

0145-ABV |

1010 1010 |

610 610 |

1254 1254 |

| 0200-SRV

0200-ABV |

1010 1010 |

610 610 |

1305 1305 |

| 0280-SRV

0280-ABV |

1010 1010 |

610 610 |

1707 1707 |

| 0400-SRV

0400-ABV |

1219 1219 |

813 813 |

1757 1757 |

|

0525-SRV 0525-ABV |

1219 1219 |

813 813 |

1757 1757 |

|

0600-SRV 0600-ABV |

1524 1524 |

914 914 |

2157 2157 |

|

0825-SRV-L 0825-SRV-V 0825-ABV-L 0825-ABV-V |

– 1524 2490 1524 |

– 940 1143 940 |

– 2157 1439 2157 |

|

1100-SRV-L 1100-SRV-V 1100-ABV-L 1100-ABV-V |

2481 1524 3053 1524 |

1292 1016 1118 1016 |

1435 2157 1435 2157 |

|

1670-SRV-L 1670-ABV-L |

2981 3258 |

1181 1283 |

1600 1601 |

Accessories

Electric Fail-Safe Valve (EFS)

| LAKOS Electric Fail-Safe Valve (EFS) is an excellent alternative to our standard Purge Valves as the EFS valve features a fail-safe option for when power is lost. If power is cut off during a purge cycle, the EFS valve uses its internal battery pack to close the valve – preventing an unexpected water loss scenario. The EFS Valve is available on all Industrial and HVAC series Separators and can be purchased with a new Separator or as a replacement for an existing valve. |

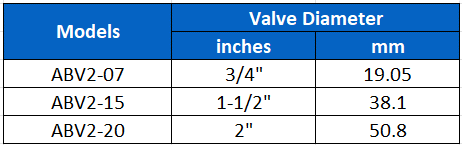

ABV2-Automatic Ball Valve

| The ABV2 purges solids automatically, eliminating manual purging. It also features an electronic circuit that adjusts motor speed to keep cycle time constant, maintaining consistent purge durations. Typical use cases are in HVAC or commercial applications. For residential applications, refer to our Accupurge valve. The ABV2 is also known as VB030 actuator.

|

HydroBoosters

SRV – Solids Recovery Vessel

|

| The Solids Recovery Vessel (SRV) captures purged solids and liquids and returns the clean liquid back to the system; resulting in a zero liquid loss solution. The SRV features continuous operation and allows for the removal of purged solids without interrupting system flow or filtration. SRV models come in three options: SRV-816, SRV-833, and SRV2-833.

|

Ask A Quote

Fill the form to get a quote or more information about the product.