Cooling Tower Side Stream Filters for Sub-Micron Filtration SPX

Cooling Tower Side Stream Filters for Sub-Micron Filtration, LAKOS SPX take a standard LAKOS TBX SideStreamClean System and pairs it with a LAKOS Cartridge Filter to create a SideStreamClean PLUS System for even finer filtration.

Description

Cooling Tower Side Stream Filters for Sub-Micron Filtration

LAKOS SPX SideStreamClean Plus

Cooling Tower Side Stream Filters for Sub-Micron Filtration, LAKOS SPX take a standard LAKOS TBX SideStreamClean System and pairs it with a LAKOS Cartridge Filter to create a SideStreamClean PLUS System.

The SideStreamClean PLUS System takes a portion of liquid from the outflow that has already gone through the LAKOS Separator and filters it through a cartridge filter for even finer or sub-micron filtration.

Flow Range: 15 – 250 m³/h

Maximum Pressure: 150 psi (10,3 bar)

Cartridge Filter Micron Ratings: 0,35, 1, 5 and 10 micron

Technical Specifications

|

Models |

Downloads |

Flow m3/hr |

Cartridge* m3/hr |

Inlet (grv/flgd) |

Outlet (grooved) |

Weight |

Pump HP |

| 0065-SRV | DWG PDF | 15 | 2.3 | 2″ grv | 1-1/2″ | 257 | 1.5 |

| 0100-SRV | DWG PDF | 23 | 4.5 | 3″ grv | 2″ | 293 | 2 |

| 0145-SRV | DWG PDF | 33 | 6.8 | 3″ grv | 2-1/2″ | 363 | 3 |

| 0200-SRV | DWG PDF | 45 | 6.8 | 3″ grv | 3″ | 378 | 5 |

| 0280-SRV | DWG PDF | 64 | 11.4 | 4″ grv | 4″ | 448 | 5 |

| 0400-SRV | DWG PDF | 91 | 11.4 | 6″ flgd | 4″ | 587 | 7.5 |

| *0525-SRV | DWG PDF | 119 | 20.4 | 6″ flgd | 4″ | 695 | 15 |

| *0825-SRV | DWG PDF | 187 | 20.4 | 8″ flgd | 6″ | 903 | 20 |

| *1100-SRV | DWG PDF | 250 | 20.4 | 8″ flgd | 6″ | 905 | 20 |

* Cartridge filters are available in 0.35, 1, 5 and 10 micron sizes.

All SideStreamClean PLUS systems are rated for 150 psi (10.3 bar) maximum pressure.

Frequently Asked Questions

[/vc_column_text][/vc_column][/vc_row]

Answer: As a rule of thumb, LAKOS uses a sizing factor of 1 GPM per square foot of basin area to determine the required size of a Tower Clean (TC) system. Using this factor, multiply the square footage of the cooling tower basin (L x W) by 1 GPM / sq. ft. This gives the basic flow rate for sizing the TC system. Tower Clean literature LS-710 can also be used as a reference for more information and equipment selections.

For industrial applications or very heavy solids loadings, consult LAKOS for recommended basin sweeping flow rates..

Answer: LAKOS factory-built purge controllers (ABV, ABV2, AKE, APP, AFS, EFS) do not have factory-set timings. The required purge frequency and durations vary depending on flow rates, solids concentrations, type of solids, etc. The controller time settings must be set at installation and LAKOS literature LS-608 can be used to help establish purge duration and frequency based on the application.

Answer: To determine the necessary purge frequency, purge often at first and calculate the proper rate based on the expected volume of separated solids. Purge duration should be long enough to evacuate the purge chamber AND clear the entire length of the purge piping of all solids. This is usually indicated by a change in the color of the purged liquid from dark to light. The time between purges should never exceed the time it takes to fill 1/3 of the collection chamber volume, based on the expected solids load and the separator’s purge collection volume, as indicated in the separator’s literature. Refer to LS-608 for additional information on calculating purge frequency and duration.

Answer: While there are many LAKOS Separators still in service after 15-25 years, there are many variables to the longevity of a LAKOS Separator. It can generally be expected to last as long as any other materials of similar construction in that system. Environment, fluid chemical make-up, flow, the material of construction, type of solids, and maintenance purging are all important factors to the life of a separator. It is important to consider all these factors when purchasing a separator. Providing LAKOS with details about your application will ensure your separator meets or exceeds the life expected through your purchase. Consult your LAKOS factory representative to obtain the life expectancy in your specific application .

Answer: As a standard, most separators are available in mild carbon steel and 304L/316L-series stainless steels. Specially designed separators can also be constructed in most weldable metals, including, but not limited to: super duplex stainless steels, chrome-moly, titanium, Hastelloy, nickel alloys, and cupronickel. In special cases, separators can also be fabricated in plastic or fiberglass. For materials other than carbon and stainless steel, consult with LAKOS on the availability of your specific material requirements.

Answer: Standard maximum temperature rating for operating most LAKOS Separators is 180°F. The exceptions are SMP Separators, which have a maximum temperature of 120°F. LAKOS can easily accommodate higher temperatures with custom separators.

Answer: Standard maximum pressure rating for most LAKOS Separators is 150 psi. The exceptions are the SMP Separators, which have a maximum pressure rating of 100 psi. Contact the factory for higher pressures; LAKOS can accommodate pressures up to 3000 psi through custom separators.

Video

Removing Dirt and Sand From Cooling Towers, Heat Exchangers, and Chillers – LAKOS |

|

|

How To Keep Cooling Tower Basins Clean All The Time – LAKOS |

|

|

Benefits of Using LAKOS Cooling Tower Basin Cleaning |

|

|

Cooling Tower Basin Cleaning – LAKOS |

|

|

LAKOS – Three Minute Settling Test |

|

|

DIMENSIONS

|

|

Accessories

Electric Fail-Safe Valve (EFS)

| LAKOS Electric Fail-Safe Valve (EFS) is an excellent alternative to our standard Purge Valves as the EFS valve features a fail-safe option for when power is lost. If power is cut off during a purge cycle, the EFS valve uses its internal battery pack to close the valve – preventing an unexpected water loss scenario. The EFS Valve is available on all Industrial and HVAC series Separators and can be purchased with a new Separator or as a replacement for an existing valve. |

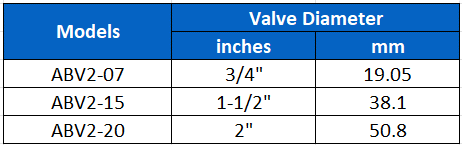

ABV2-Automatic Ball Valve

| The ABV2 purges solids automatically, eliminating manual purging. It also features an electronic circuit that adjusts motor speed to keep cycle time constant, maintaining consistent purge durations. Typical use cases are in HVAC or commercial applications. For residential applications, refer to our Accupurge valve. The ABV2 is also known as VB030 actuator.

|

HydroBoosters

SRV – Solids Recovery Vessel

|

| The Solids Recovery Vessel (SRV) captures purged solids and liquids and returns the clean liquid back to the system; resulting in a zero liquid loss solution. The SRV features continuous operation and allows for the removal of purged solids without interrupting system flow or filtration. SRV models come in three options: SRV-816, SRV-833, and SRV2-833.

|

Ask A Quote

Fill the form to get a quote or more information about the product.