-

1. Χημικά Επεξεργασίας Νερού και Αποβλήτων (4)

-

2. Χημικά και Συσκευές για Πισίνες και Spa (118)

-

3. Ειδικά Καθαριστικά Βιομηχανίας και Ναυτιλίας (36)

-

4. Οικιακές Αντίστροφες Ωσμώσεις και Φίλτρα (88)

-

5. Βιομηχανικές Μονάδες Επεξεργασίας Νερού (99)

-

6. Ανακύκλωση Αποβλήτων με Εξατμιστήρες Κενού (6)

-

7. Μον. Επεξεργασίας Βιομηχανικών Αποβλήτων (5)

-

8. Φιλτρόπρεσες και Ανταλλακτικά (1)

-

9. Oil Skimmers Απομάκρυνσης Λαδιών (4)

-

10. Αεροκίνητες Διαφραγματικές Αντλίες (30)

-

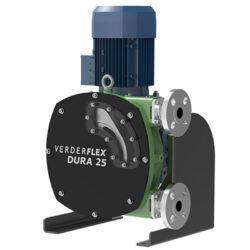

11. Περισταλτικές Αντλίες Verderflex (17)

-

12. Αντλίες Χημικών και Βιομηχανικός Εξοπλισμός (36)

-

13. Ηλεκτρομαγνητικές Δοσομετρικές Αντλίες (62)

-

14. Δοσομετρικές Αντλίες Ηλεκτροκίνητες (49)

-

15. Δοσομετρικές Αντλίες Ειδικών Εφαρμογών (73)

-

16. Υλικά Απορρύπανσης και Συλλογής Διαρροών (105)

-

17. Προϊόντα Συγκράτησης Διαρροών και Ρυπάνσεων (72)

-

18. Μεταλλικά Ερμάρια Αποθήκευσης Χημικών (46)

-

19. DrumClip για Ασφαλή Μεταφορά Βαρελιών (3)

-

20. Πλαστικές Δεξαμενές Χημικών και Αποβλήτων (18)

-

21. Όργανα και Τεστ Κιτ Ανάλυσης Νερού (124)

-

22. Βιολογικοί Καθαρισμοί Compact (1)

Κατηγορίες Προϊόντων

- Home

- Προϊόντα